optimising offshore decommissioning: boosting emissions and cost savings

why emissions matter in offshore decommissioning

Decommissioning costs are rising as carbon taxes, fuel price volatility and stricter regulatory requirements begin to shape project economics. Operators who treat emissions as an afterthought risk higher costs, delays and compliance challenges.

By integrating emissions forecasting and optimisation into early planning, projects can achieve measurable cost savings, regulatory readiness, and a more resilient project design.

decommissioning options compared

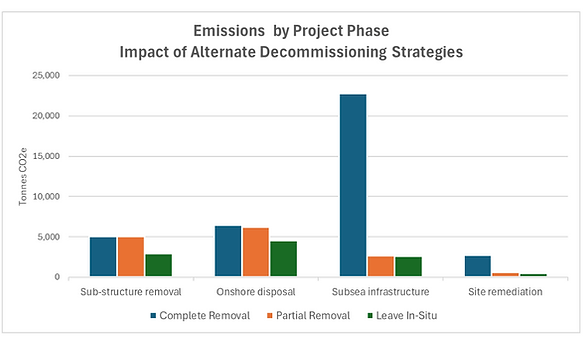

A case study was developed based on a published North Sea decommissioning project Environmental Appraisal Report and then extended to compare the emissions impacts of complete versus partial removal, highlighting potential advantages of leaving infrastructure in place.

By quantifying emissions at each phase and integrating this data into analysis of their programme strategies, operators can make data-driven decisions and potentially uncover hidden inefficiencies.

A North Sea project involving two manned platforms with associated subsea installations and pipelines was assessed to reveal the scale of opportunity.

While there are a wide range of strategies that need to be considered in developing a decommissioning programme, such as timing of Cessation of Production (COP) and plug & abandonment (P&A) of wells, this case study has focussed on three strategies for infrastructure removal:

-

Complete Removal - All infrastructure is fully removed from the seabed.

-

Partial Removal - Pipelines are left buried in place, with topsides and jackets fully removed.

-

Leave in Situ - Topsides are removed, but substantial infrastructure, including jacket footings and pipelines, remains on or below the seabed, ensuring safety and navigation guidelines are met.

emissions and costs at a glance

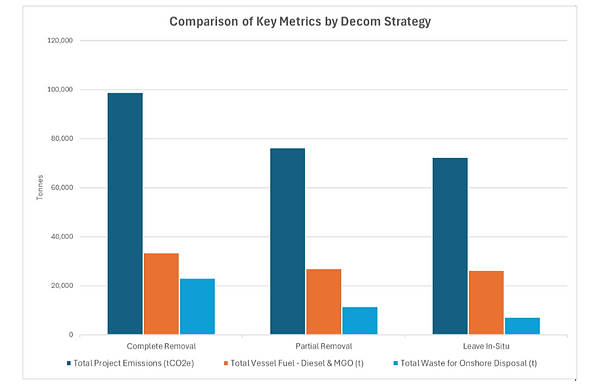

A summary of the emissions, fuel and waste calculated for the three scenarios are shown below.

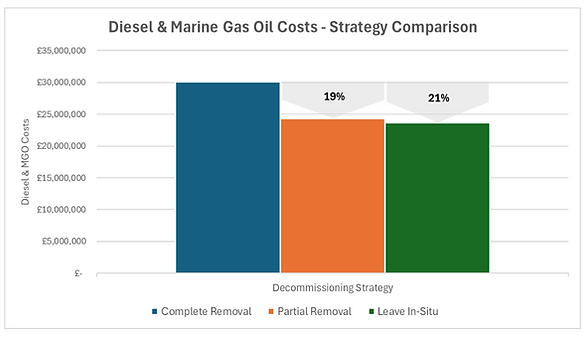

Altogether, in this scenario, moving from complete removal to leave-in-situ could achieve up to around £6 million (21%) in cost savings and close to 30% lower emissions. Leaving some structures in place can also help to preserve seabed habitats and well-established marine communities and artificial reefs, provided safety and navigation standards are met. Obviously each project is different, requiring consideration of specific infrastructure to ensure removal is done in an optimal and safe way, however this example indicates the scale of potential savings in CO2e and costs.

why all of this matters

The bulk of emissions in decommissioning programmes comes from running vessels and heavy equipment during well P&A, removal, and disposal operations. By reducing the scale of removal and optimising vessel use, operators can significantly reduce their emissions and operational costs. Lower fuel use also means shorter project duration and reduced risk exposure.

There can be an ecological upside, too. Leaving some structures in place helps preserve seabed habitats and well-established marine communities, provided safety and navigation standards are met. Platforms and footings often function as artificial reefs, boosting biodiversity where they stand. This is supported by a number of studies as part of the “Rigs-to-Reefs” impact assessments that have been conducted in the United States Gulf of Mexico and the California Pacific coast.

regulatory trends and strategic takeaways

While UK law generally expects complete removal, derogations allowing partial removal are possible given strong environmental and cost-benefit cases. Australia’s regulations likewise favour complete removal as the default, but are increasingly open to innovation as operators demonstrate significant environmental and emissions improvements.

Scenario modelling with emissions forecasting tools enables operators to present data-driven options to regulators, comparing the full impact, including financial and environmental effects, of each approach. This method is quickly becoming industry best practice and sets the stage for smarter, more sustainable decommissioning strategies.

Emissions-optimised plans are also cost-optimised.

By accounting for future carbon pricing, minimising vessel fuel use and aligning with upcoming regulatory expectations, this approach demonstrates how emissions analysis is not an “add-on” but a direct driver of financial and operational efficiency.

As global decom activity accelerates, projects that embed emissions considerations now will deliver the lowest long-term cost, the strongest compliance position, and lasting environmental benefit.

the bottom line